Corrosion of aluminium profiles

Prevent staining and ensure proper storage and handling

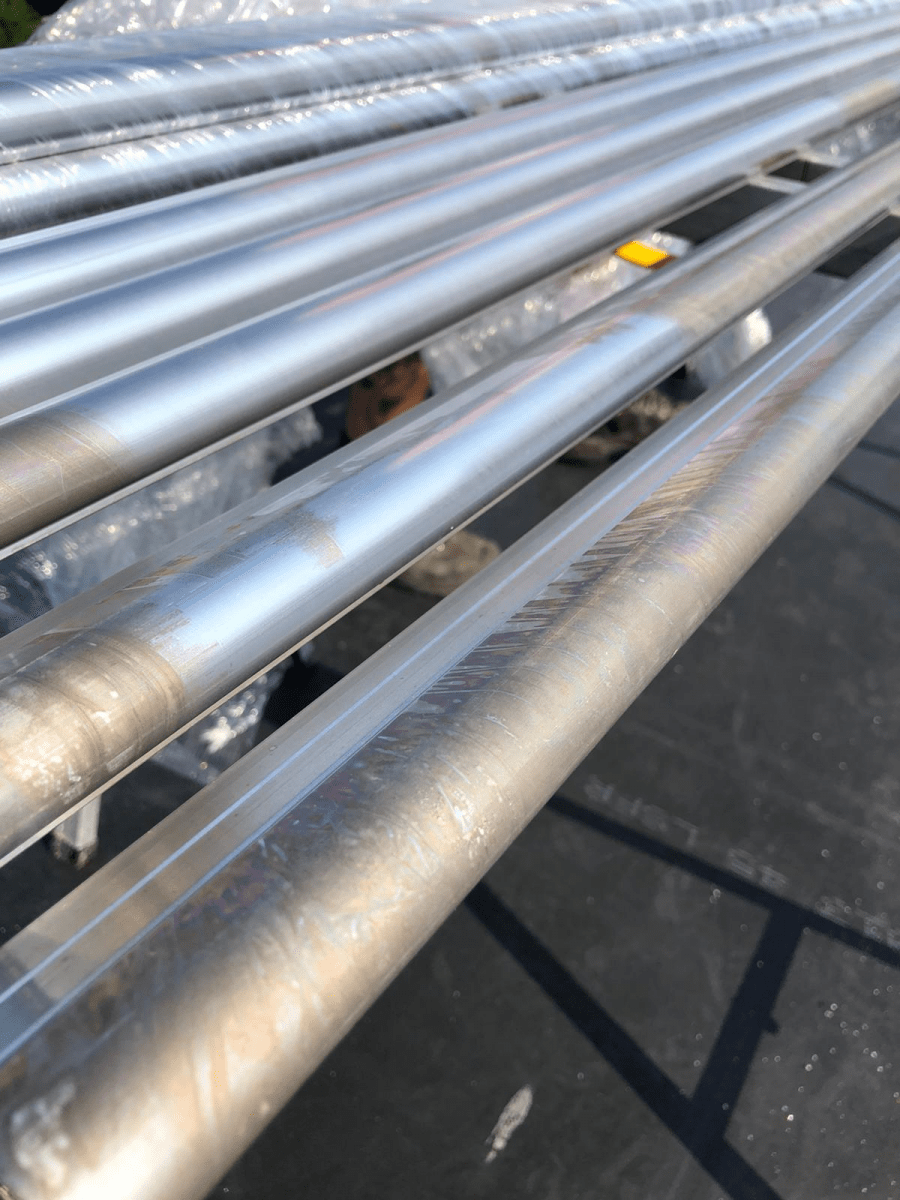

We occasionally receive reports that our aluminium roof edges are showing stains in some places due to corrosion. That’s not a nice sight of course. This is almost always due to incorrect storage of our aluminium roof edges, wall copings or other aluminium profiles on the building site or incorrect handling. You can do something about that quite easily. Below we explain what aluminium corrosion is, the advantages of corrosion, and what you can do to prevent corrosion staining.

One of the differences between precious metals like gold, silver or platinum and base metals like iron and aluminium is that precious metals are less susceptible to oxidation than base metals. In the case of aluminium, this need not be a problem at all. Aluminium is affected by corrosion. This is a natural chemical attack on the metal by environmental influences and in particular by so-called electrochemical reactions. Without going into too much detail about this process, corrosion changes the surface of aluminium into a metal oxide. You might think that this is a bad thing.

Corrosion provides a protective layer

Nothing could be further from the truth. Instead, a more stable surface is created which acts as a protective layer. This layer prevents further corrosion of the aluminium. Corrosion occurs when aluminium comes into contact with water and oxygen. Iron will rust and copper will turn green in similar circumstances. In the case of aluminium an oxide skin is formed which - if evenly sealed - prevents further corrosion of the aluminium under that layer. This can cause the aluminium to turn white. This is also known as ‘white rust’, but this is far too negative a term because a protective layer is formed. That’s not the case with real rust. This is one of aluminium’s qualities: it is corrosion-resistant.

Ensure proper storage and prevent staining

But watch out! If the corrosion occurs evenly, there is no problem. If for example aluminium roof edges are delivered to the roof in the protective foil, we recommend installing the roof edges quickly. It is best to transport and store the aluminium profiles free of moisture. Aluminium is a good heat conductor. It often feels cold and attracts moisture which finds its way under the foil. If there is insufficient ventilation between the profiles - and therefore a lack of evaporation - corrosion will occur. If the foil is still around the profiles, this corrosion will be more local. It will result in undesired staining. It is best to store aluminium profiles - whether roof edges, sills or wall copings - dry (indoors) at a constant temperature and with sufficient ventilation. The foil should also be removed before staining can occur.

Stress corrosion cracking

As mentioned, aluminium is corrosion-resistant but it is not resistant to stress corrosion which can cause cracks. This is caused by moisture and excessively high temperatures. How can stress corrosion cracking be prevented? Avoid (excessively) high temperatures. This is not such a big problem in the Netherlands; stress corrosion cracking is reduced at 50°C. Avoid snipping, cutting or hammering as much as possible during installation and make sure that the roof edges, sills or wall copings do not come into contact with chlorides and nitrates. Last but not least: if it is not necessary to weld aluminium profiles or corner joints together at the building site, do not do so. Welds and transitions from thick to thin or vice versa can increase the likelihood of stress corrosion cracking. Ask for our high-quality, custom-made solutions so as little processing as possible takes place on the building site. In short, if you take the above precautions you or your customers can enjoy the aesthetic qualities of our aluminium building products for a long time to come.

Do you need more information or have you any questions?

Get in touch with us

We are happy to help. More information can be found on our contact page.