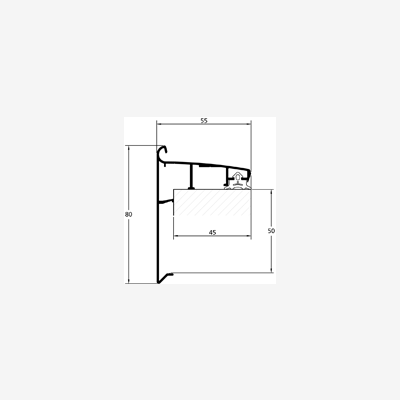

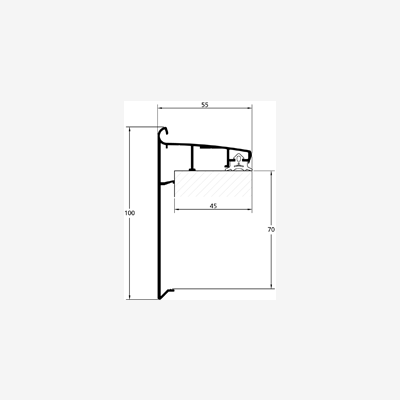

Roval-Solo

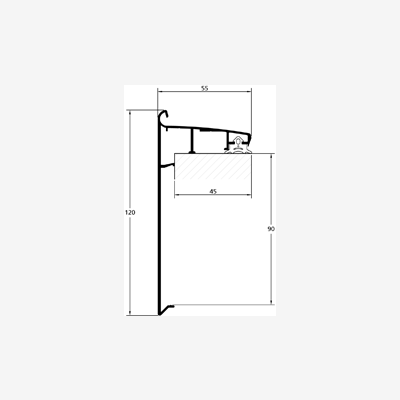

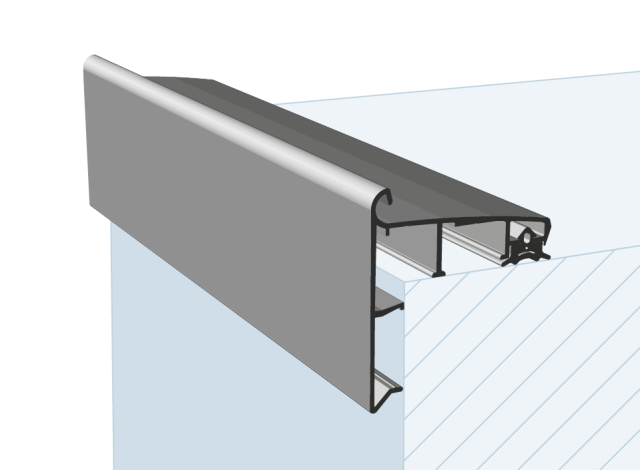

The Roval Solotrim® is a patented, single-roof trim fitted with a specially developed EPDM sealing tape. The roof trim is fitted directly onto the finished roof covering using stainless steel screws and stainless steel neoprene sealing rings. Suitable for both bituminous and synthetic roof covering. Screw holes are provided as standard. In lengths from 2500 mm.

The Solotrim has pre-drilled holes (Ø 6 mm) in the tail-piece of the trim, 50 mm from the ends and spaced at distances of 300 mm. The cover click-coupling is made in a special UV-resistant quality and seals the expansion joints between the individual roof trims. The joint at the front of the Solotrim is linked with an aluminium connecting plate with a thickness of 2.0 mm. This plate has a width of 40 mm. The Solotrim slides into a recess with a bevelled edge in this plate. The purpose of the bevelled edge is to provide a mounting stop. Its dimensions allow the absorption of any expansion due to changes in temperature (1 mm/m1).

Points of interest:

Design:

- The roof edge trim must be anchored to the sub-construction and must be suitable for the application of a bituminous or synthetic finish. The roof trim must be windproof.

- The top of the roof edge trim must be finished with a wall plate. The thickness of this wall plate must be at least 18 mm.

- The top of the roof trim must drain towards the plane face of the roof.

- When the bituminous or synthetic edging strips are fitted, it must be ensured that no level differences arise at the overlapping sections.

- Make internal and external angles with welded corner pieces.

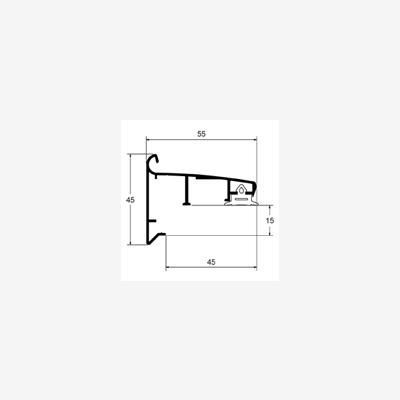

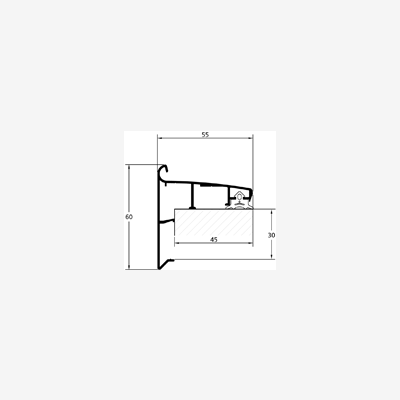

- Match the height of the Solotrim with the thickness of the wall plate. The underlying façade joint must be covered over a distance of at least 15 mm.

Execution:

- The architectural roof trim must be completely carried out and finished before the roof covering is applied. The roof trim must be windproof.

- Stone or metal roof trims must be pre-coated with a bituminous solution if a finish with bituminous edging strips is applied.

- The connection of the bituminous and plastic edging strips must be carried out level and windproof. The width of the bituminous edging strips is 1.1 metres maximum.

- The overlaps of the edging strips must allow for the Solotrim to be connected level. As a result, the connection between the Solotrim and the roof edge finishing will be watertight.

- The work can be carried out with an open flame if the trim is fireproof.

Installation:

In principle, start with a welded 500 x 500 mm corner piece (A) followed by the full lengths. The profiles are fitted with pre-drilled screw holes and EPDM sealing tape.

Adjacent profiles are connected via an aluminium connecting plate at the front. This plate has a width of 40 mm. The Solotrim slides into a recess with a bevelled edge in this plate (B). The aluminium connecting plate has an integrated spacer, which automatically ensures the required expansion joint distance of 4 mm (C) during installation.

Align the Solotrim and screw in the wooden wall plate with stainless steel/neoprene sealing rings (D).

Cover the top of the expansion joint with a synthetic cover click-coupling (E).

Do you need help in making the right choice? Ask one of our specialists

Contact us or request price quotation directly.

Be inspired!

View our completed projects with Roval-Solo